> Overview: News

> Overview: Service

> Overview: About

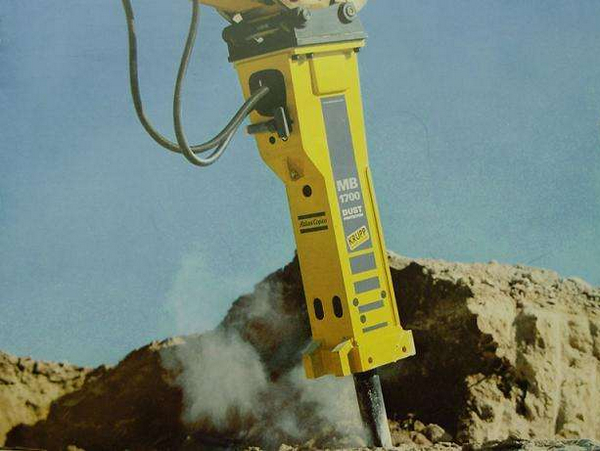

A hydraulic breaker is one of the most

commonly used attachments for excavators, frequently required for demolition,

mining, and urban construction projects. How should hydraulic breakers be

properly maintained and serviced? How should they be correctly used? These

questions are of critical importance.

Maintenance

Given the harsh operating conditions

hydraulic breakers face, proper maintenance can reduce machine failures and

extend their service life. In addition to maintaining the main machine

correctly, the following points should also be noted:

1. Visual Inspection

Check if any bolts are loose; inspect if

the connecting pins are excessively worn; verify if the gap between the chisel

and its sleeve is normal; and check if there are any oil leaks from the

hydraulic breaker or its piping.

2. Lubrication

Lubricate the lubrication points of the

working components before each operation and after every two consecutive days

of continuous operation.

3. Hydraulic Oil Replacement and

Inspection

The hydraulic oil for engineering machinery

using a hydraulic breaker should be replaced after 600 hours of operation.

Additionally, ensure the hydraulic oil temperature remains below 800°C.

The choice of hydraulic oil directly

impacts the efficiency of the hydraulic breaker. In summer, anti-wear 68#

hydraulic oil is recommended; in winter, anti-wear 46# hydraulic oil is

recommended.

Select hydraulic oil appropriately based on

the specific working environment of the equipment. Using contaminated hydraulic

oil may cause malfunctions in the breaker and the main body of the construction

machinery, as well as damage to components. Therefore, please pay special

attention to the quality of the hydraulic oil.

Usage

Proper operation can improve the efficiency

of the breaker and extend its service life. The following are important

operational precautions:

1. Before each use, inspect the high-pressure

and low-pressure oil lines for leaks or loose connections. Additionally,

regularly check other areas for leaks to prevent oil lines from detaching due

to vibration, which could cause malfunctions.

2. During operation, the chisel should always

remain perpendicular to the rock surface and be firmly pressed against it.

After breaking, immediately cease operation to prevent empty strikes.

Continuous aimless impact may damage the front section of the breaker and cause

severe loosening of the main bolts, which could potentially damage the main

unit itself.

3. Do not shake the chisel rod during breaking

operations, as this may cause the bolts and chisel rod to break.

4. It is strictly prohibited to operate the

breaker in water or muddy conditions. Except for the chisel rod, the front

guard of the breaker must not be submerged in water or mud.

5. When breaking larger hard objects (rocks),

start from the edge. Regardless of the size or hardness of the rock, starting

from the edge is usually the most feasible approach. If continuous striking at

the same point for over a minute fails to break the object, change the striking

point and try again.

2025-01-21

2020-07-08

2020-08-24

2020-01-21

2019-12-25

2019-11-01

2021-02-01

2020-10-26

2021-01-14

2020-12-11

2020-07-04

2020-09-30